Chapter 1 : Real situation of promotion of local DX in Thailand from collection of accumulated data to effective utilization

In order to promote DX in the manufacturing industry, it is of utmost importance to accurately collect built-up data. On the other hand, in Thailand, there are many manufacturing field where the basic is not established, and we often hear the worries that they do not know what to start with. At Thai NS Solutions, we work with our clients to review their entire operations from a bird's-eye view to identify and prioritize the issues that are hidden in the field . After that, we study the IT roadmap that the customers should aim for and proceed with the system implementation, thereby steadily achieving cost reduction and improvement of manufacturing quality by improving operational efficiency at the manufacturing field.

In this column, over next few articles, we will introduce the key points of DX promotion in Thailand from our viewpoint with some case studies.

In the manufacturing industry, DX means not only accumulating the know-how and data developed in the manufacturing field as experience, but also making information to easier share in digitization. The goal is to use this information to shorten lead times, increase productivity, and improve quality, and make innovation in the profit model.

The key to success in DX is to effectively utilize the data collected and feed it back to management resources.

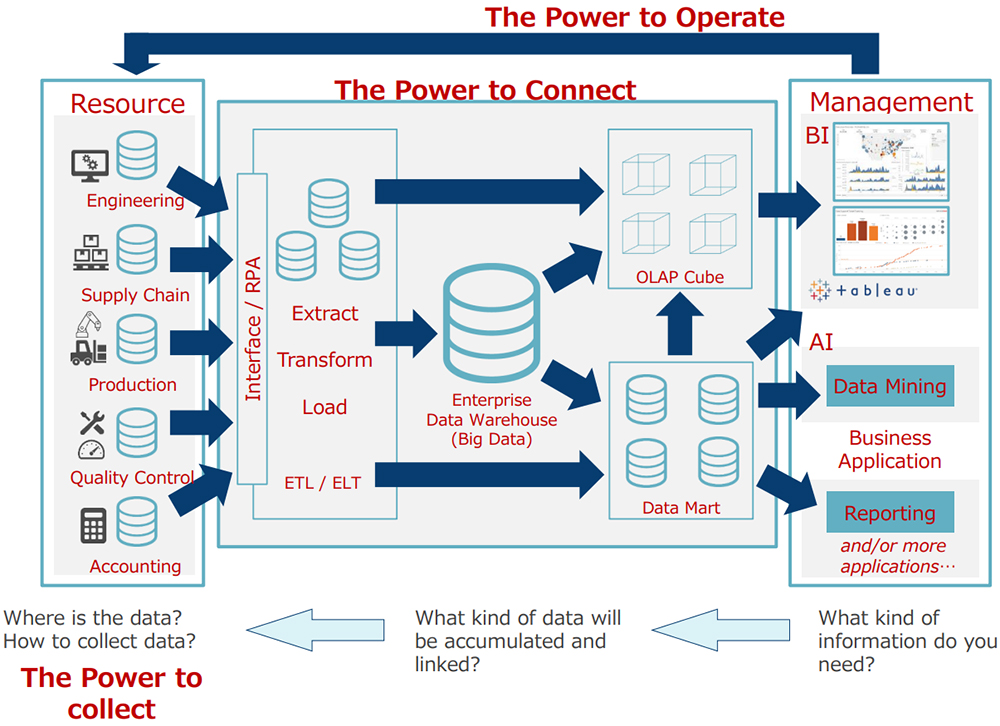

The ideal form of DX is to have the "Power to Connect" to control a variety of data using cloud, big data, and analytics, and the "Power to Operate" to utilize that data in BI, AI, and other applications for management to be in sync turn like gears.

To achieve this, it is assumed that the data is collected accurately.

▲DX roadmap image for a manufacturing industry

(Source) Nippon Steel Group's Medium-Term Management Plan "Power to Connect" and "Power to Operate" dated March 15, 2021

DX is becoming more widespread in Thailand, but the current situation is that there are many manufacturing scene where the underlying data collection is inadequate.

For example, the case where the match between goods and information has not been realized at the manufacturing field. In such case, no matter that based on the data, and a mechanism is in place to make decisions quickly, no results will be obtained. Making corrections based on data that does not accurately reflect the actual situation may only confuse in the field.

The above is a case of a company aiming for DX and data utilization, but there are many companies that are a step before that and are spending a lot of time and manpower on inefficient manual work, thinking that it is “The norm”. Here in Thailand, it is not always the case that simply introducing a system will work, but there are many cases where the introduced system is left unused or not used properly because the workers do not know how to use it properly. As a result, compared to companies that have been steadily promoting IT every year, those are already far behind at the starting stages of promoting DX. Data utilization by Western and Chinese companies is progressing and we would like to promote the introduction of IT together at an early stage.

In the next chapter, we will introduce an example of systemization through data utilization in general and the strengths of Thai NS Solutions.

28-01-2022