- Essential Functions Required for Execution in the Manufacturing Plant

MES (Manufacturing Execution System) refers to the 'manufacturing execution system' that manages and oversees the manufacturing process, providing instructions and assistance to workers. Its greatest feature is its ability to coordinate with each manufacturing process on the production line, giving directions and support to workers and managing the progress of the manufacturing process and grasping actual results. Additionally, because it is possible to understand the production status of work-in-progress items in real-time, one can expect benefits such as designing work schedules based on production plans, improving the efficiency of workers' tasks, and enhancing productivity.

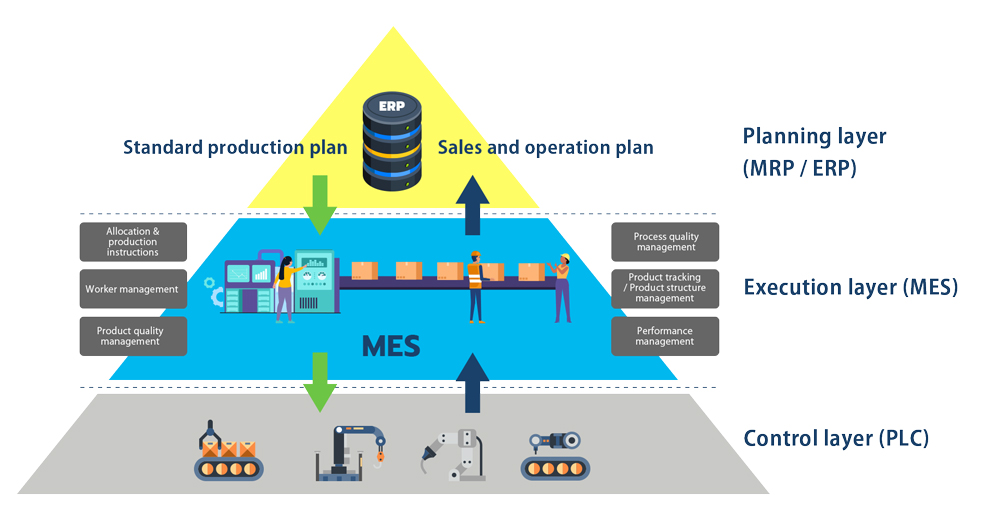

While MES is often confused with ERP (Enterprise Resource Planning), their relationship can be understood from the following diagram: ERP sits above MES as its higher-order system. ERP encompasses sales management, production management, accounting management, etc., whereas MES manages the execution layer. Additionally, below MES is the control layer, which consists of equipment control systems essential for MES processing, collecting necessary data.

With globalization, digitalization, and the diversification of needs, the product lifecycle has become shorter, and the demand for small-volume production of a wide variety of products is increasing in the manufacturing field. To address this trend, the adoption of MES is rapidly increasing and garnering attention.

We are not equipped to handle product traceability, and thus, are not meeting our customers' demands

Since we can't immediately identify the issues occurring on-site, it leads to major problems

I want to understand the extent of defective product occurrences and consider improvement measures

Since we are recording results on forms by handwriting, the accuracy of the information is low

Regarding the production plan, we cannot grasp how many of what items are being produced on-site, and we don't know the progress

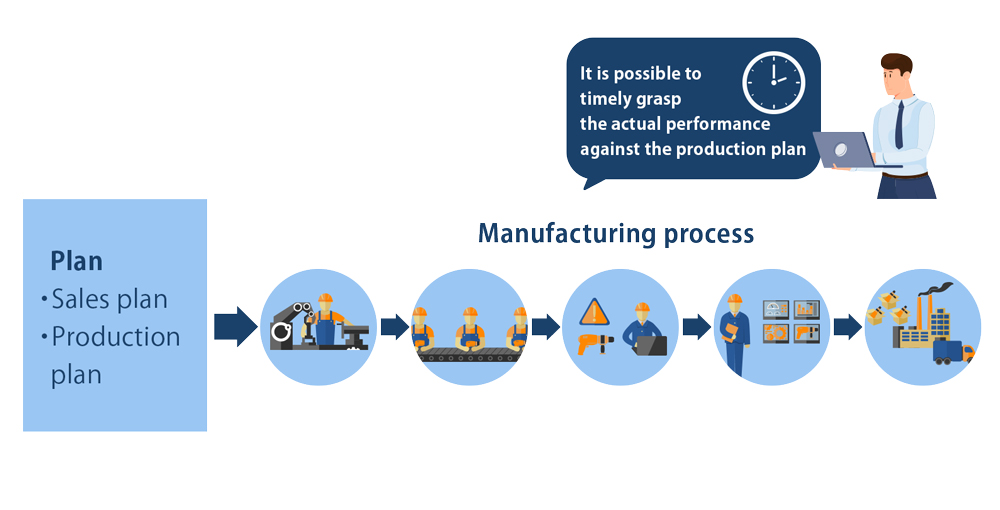

With the introduction of MES, it becomes possible to timely grasp the actual manufacturing performance against the production plan. Therefore, delays against the plan can be detected early, and by taking appropriate measures, manufacturing in line with the plan can be realized.

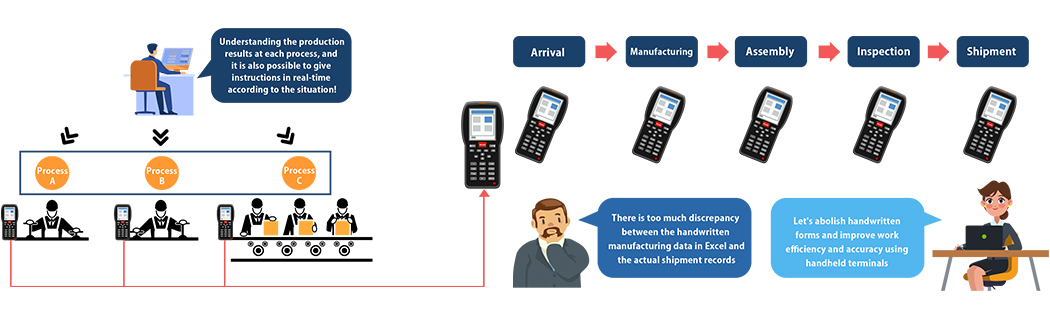

With the introduction of MES, it becomes possible to track the progress of a product's production status in real-time. By setting up an environment where the production process can be understood, data such as 'when', 'where', and 'by whom' each step was addressed can be collected.

Therefore, even if there is an issue after shipment, the origin of the problem can be identified from the manufacturing performance history, leading to more specific countermeasures and strategies to avoid such issues in the future.

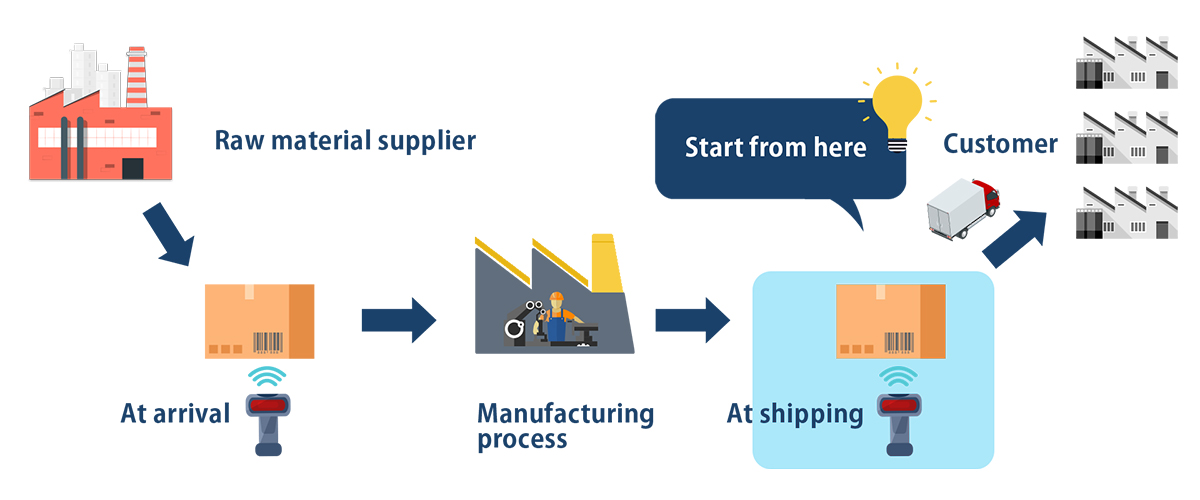

With the introduction of MES, it is possible to record the actual delivery of raw materials, the actual introduction to the production line, and manufacturing performance at each process using handheld terminals. This leads to improved work efficiency and increased information accuracy by reducing paper media. Additionally, since the data is stored in the system as actual performance, checking and searching past records becomes easier

The MES area often requires customization to cater to the unique characteristics of products and production lines. Therefore, applying a standard package solution can be challenging, potentially leading to increased costs and longer implementation periods.

You can begin with specific business areas such as raw material arrival, manufacturing, and product shipment, and then progressively build up the MES.

With a template-based approach, it's possible to implement at a low cost and within a short time frame. Since it's a template developed in-house, it can flexibly cater to the unique characteristics of the customer's products and production lines, as well as their specific company requirements

We offer a combined implementation with Microsoft Dynamics ERP to meet the customer's request to start with ERP + barcode initially

✔ Dynamics 365 For Finance and Operations (former name Dynamics AX)

✔ Dynamics 365 Business Central (former name Dynamics NAV)

・Hearing your current issues and requests

・Plan the scope and schedule of implementation

・Project planning and proposal

・Business flow creation

・Master design

・Customization design

・Testing, migration, and operation planning

・Master creation support

・Customized development

・System setup

・Migration rehearsal

・System testing

・Migration rehearsal

・System testing

・Manual creation

・Key user training

・User acceptance testing support

・On-site support

・Online Q&A support

・Problems solving support

Continuous support throughout the system lifecycle, from implementation studies to maintenance support once the project started

Define requirements while coordinating the opinions of the Thai people in the field and management.

Able to handle projects with a multilingual communication using Japanese, English, and Thai

Provide a maintenance menu based on the degree of system operation, including extensive support in the initial stage of operation.

Our in-house team of experienced consultants will provide you with the best solution

Minimize the risk of system implementation failure by executing the project responsibly in each phase with the client's agreement.

System Engineering &Planning 1

Manager

Paskorn Manee

System Engineering &Planning 1

Manager

Paskorn Manee

We offer implementation support services that cover everything from overall design to full operation, as well as post-operational improvement proposals and monitoring. We take a detailed look at your specific business requirements and ensure the optimal implementation and operation.

If you would like to learn more about the functionalities of MES or if you need a quotation or proposal, please feel free to contact us.